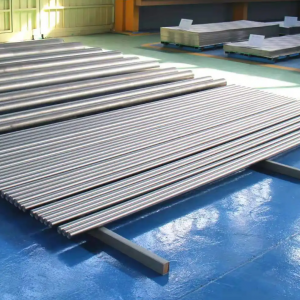

Superalloy InconelX-750/ UNS N07750/ AlloyX-750 Pipe e Seamless, Sheet, Wire

Lihlahisoa tse fumanehang

Tube e se nang seam, Plate, Ropa, Forgings, Fasteners, Pipe Fittings

Maemo a Tlhahiso

| Sehlahisoa | ASTM |

| Libara le Forgings | B 637 |

Sebopeho sa Lik'hemik'hale

| % | Ni | Cr | Fe | C | Mn | Si | S | Ti | Nb+Ta | Al | Co | Cu |

| Min | 70.0

| 14.0 | 5.0 |

|

|

|

| 2.25 | 0.70 | 0.40 |

|

|

| Max | 17.0 | 9.0 | 0.08 | 1.00 | 0.50 | 0.010 | 2.75 | 1.20 | 1.00 | 1.00 | 0.50 |

Lintho Tsa 'Mele

| Botenya | 8.28 g/cm3 |

| Ho qhibiliha | 1393-1427 ℃ |

Lisebelisoa tsa Inconel X-750

Inconel X-750 alloy haholo-holo ke superalloy e thehiloeng ho nickel e matlafalitsoeng ka lilemo ka γ[Ni3(Al, Ti, Nb)] phase.E na le khanyetso e ntle ea kutu le khanyetso ea oxidation ka tlase ho 980 ℃, 'me ka tlase ho 800 ℃ E na le khanyetso e phahameng ea kutu.E na le khanyetso e ntle ea ho phomola ka tlase ho 540 ° C, hammoho le sebopeho se setle le ho chesehela.Alloy ena e sebelisoa haholo-holo bakeng sa ho etsa lienjene tsa lifofane tse sebetsang ka tlase ho 800 ° C 'me li hloka matla a phahameng..Lithaba le tsona li ka sebelisoa ho etsa likhaba tsa turbine tsa mouoane le likarolo tse ling, joalo ka lipoleiti, likhoele, mekoallo, forgings, mehele, lithapo, liphaephe, jj.

Inconel X-750 Heat Treatment Process

Sistimi ea kalafo ea mocheso oa tharollo bakeng sa lipoleiti, likhoele le liphaephe sebakeng sa phepelo ke 980 ℃ ± 15 ℃, ho pholisa moea.Bakeng sa tsamaiso ea bohareng ea mocheso oa thepa le likarolo, mekhoa e latelang e ka khethoa bakeng sa phekolo ea mocheso.

Anealing: 955~1010℃, ho futhumatsa metsi.

Ho kenngoa ha likarolo tse cheselitsoeng pele ho tjheseletsa: 980 ℃, 1h.

Ho imolla khatello ea kelello ea likarolo tse cheselitsoeng: 900 ℃, ho nosetsa bakeng sa 2h.

Ho fokotsa khatello ea maikutlo: 885 ℃ ± 15 ℃, 24h, pholile ea moea.

Inconel X-750 Mefuta e Fumanehang le Litlhaloso

Li-bar, forgings, rings, sheet-rolled sheets, sheet-rolled sheets, strips, tubes and wires li ka fanoa ka boholo bo fapaneng.

Lipoleiti le li-strip hangata li fanoa ka mor'a ho kolobisoa ho chesang kapa ho batang, ho kolobisoa kapa tharollo, ho kha le ho bentša.

Li-bar, forgings le mehele li ka fanoa sebakeng sa fored kapa se chesang;li ka boela tsa fanoa ka phekolo ea tharollo ka mor'a ho forging;mekoallo e ka fanoa ka mor'a tharollo 'me ea belisoa kapa ea fetoloa,' me e ka fanoa ka serame ha odara e hloka hore Pull state e be teng.

Mohala o ka fanoa ka boemo bo tiileng ba tharollo;bakeng sa terata e nang le bophara ba lebitso kapa botenya ka tlase ho 6.35mm, e ka ba tharollo e tiileng 'me e fanoa ka deformation e batang ea ho taka ea 50% ho ea ho 65%;bophara ba lebitso kapa bolelele ba lehlakore bo boholo ho feta 6.35mm.Wire, ka mor'a phekolo ea tharollo, e fanoa ka deformation e batang e seng ka tlase ho 30%.Bakeng sa lithapo tse nang le bophara ba lebitso kapa bolelele bo sa feteng 0.65mm, li ka fanoa ka deformation e batang e seng ka tlase ho 15% kamora kalafo ea tharollo joalo ka ha ho hlokahala.

Inconel X-750 Libaka tsa Kopo

Alloy e sebelisoa haholo-holo bakeng sa ho etsa liliba tsa makhasi le liliba tsa coil tse nang le litlhoko tse phahameng tsa matla le ho hanyetsa ho phomola bakeng sa lienjine tsa moea tse sebetsang ka tlase ho 800 ° C.E ka boela ea sebelisoa ho etsa likarolo tse kang li-blades tsa turbine.Mefuta e fumanehang ke lakane, strip, bar, forging, ring, terata le tube.