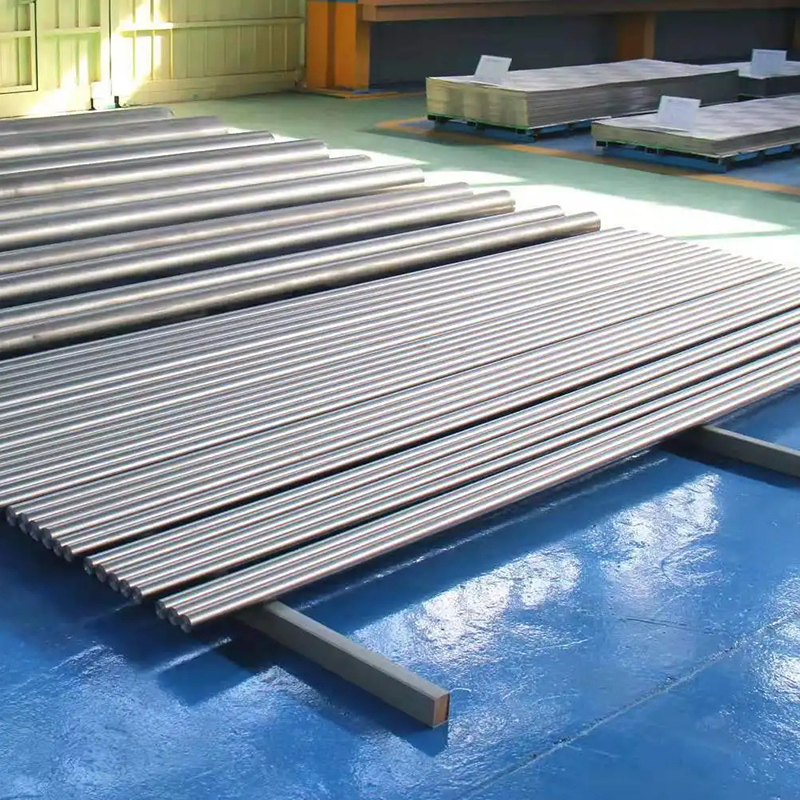

S32205/ S31803 Tube, Plate, Bar

Lihlahisoa tse fumanehang

Tube e se nang seam, Plate, Ropa, Forgings, Fasteners, Pipe Fittings.

Maemo a Tlhahiso

| Sehlahisoa | ASTM |

| Li-bar, strips le profiles | A 276, A484 |

| Letlapa, Leqephe le Lekhapetla | A 240, A480 |

| Liphaephe tse se nang Seam le tse cheselitsoeng | A 790, A 999 |

| Lisebelisoa tsa Pipe tse Seamless le tse Welded | A 789, A 1016 |

| Lisebelisoa | A 815, A960 |

| Li-flange tsa lipeipi tse entsoeng kapa tse phuthoang le lisebelisoa tse entsoeng | A 182, A961 |

| Ho theha li-billet le li-billet | A 314, A484 |

Sebopeho sa Lik'hemik'hale

| % | Fe | Cr | Ni | Mo | C | Mn | Si | P | S | N |

| Min | Ho leka-lekanya | 22.0 | 4.5 | 3.0 | 0.14 | |||||

| Max | 23.0 | 6.5 | 3.5 | 0.030 | 2.00 | 1.00 | 0.030 | 0.020 | 0.20 |

Lintho Tsa 'Mele

| Botenya | 7.69 g/cm3 |

| Ho qhibiliha | 1385-1443 ℃ |

Lisebelisoa tsa S32205

ASTM A240/A240M--01 Duplex stainless steel 2205 alloy ke tšepe e sa hloekang e habeli e entsoeng ka 22% chromium, 2.5% molybdenum le 4.5% nickel-nitrogen alloy.E na le matla a phahameng, matla a ts'usumetso e ntle le ho hanyetsa ho bola ha khatello ea kelello ka kakaretso le ea lehae.Matla a tlhahiso a 2205 duplex stainless steel a feta habeli a tloaelehileng a austenitic stainless steel.Tšobotsi ena e lumella baqapi ho fokotsa boima ba 'mele ha ba etsa lihlahisoa, ho etsa hore motsoako ona o theko e tlaase ho feta 316 le 317L.Alloy ena e loketse haholo ho sebelisoa sebakeng sa mocheso oa -50°F/+600°F.Bakeng sa lisebelisoa tse ka ntle ho mocheso ona, motsoako ona o ka boela oa nkoa, empa ho na le mefokolo e itseng, haholo-holo ha e sebelisoa ho mehaho e cheselitsoeng.

Melemo ea S32205 Duplex Steel

1.Matla a lihlahisoa a feta habeli a tšepe e tloaelehileng ea austenitic, 'me e na le litlhoko tse hlokahalang tsa ho theha.

Plastiki e lekaneng.Botenya ba lerako la litanka tsa polokelo kapa likepe tsa khatello tse entsoeng ka tšepe e sa hloekang ea duplex ke 30-50% e tlase ho feta ea austenite e sebelisoang hangata, e thusang ho fokotsa litšenyehelo.

2.E na le khanyetso e ntle ea khatello ea maikutlo ea kutu.Esita le tšepe e sa hloekang ea duplex e nang le motsoako o tlaase ka ho fetisisa e na le khanyetso e phahameng ea khatello ea maikutlo ho senya ho feta tšepe e sa jeleng ea austenitic, haholo-holo tikolohong e nang le li-ion tsa chloride.Stress corrosion ke bothata bo hlahelletseng boo ho leng thata ho bo rarolla ka tšepe e tloaelehileng ea austenitic.

3.Ho hanyetsa kutu ea tšepe e sa hloekang ea 2205 e sebelisoang ka ho fetisisa mecheng e mengata ea mecha ea litaba e molemo ho feta ea 316L ea tšepe e sa hloekang ea austenitic, ha tšepe e sa hloekang ea super duplex e na le khanyetso e phahameng ka ho fetisisa ea ho senya, le mecheng e meng ea litaba, e kang acetic acid, formic acid E ka ba ea nka sebaka sa tšepe e sa hloekang ea alloy austenitic, esita le li-alloys tse hanang ho bola.

4. E na le khanyetso e ntle ea corrosion ea lehae.Ha ho bapisoa le tšepe e sa jeleng ea austenitic e nang le li-alloy tse lekanang, ho hanyetsa ha eona ho corrosion ho hanyetsa le mokhathala o hanang ho senya ho molemo ho feta tšepe e sa jeleng ea austenitic.

5. Coefficient ea katoloso ea linear e tlase ho feta ea austenitic stainless steel, e haufi le ea carbon steel.E loketse ho hokahanya le tšepe ea carbon 'me e na le bohlokoa ba bohlokoa ba boenjiniere, joalo ka tlhahiso ea lipoleiti tse kopantsoeng kapa li-linings.

6. Ho sa tsotellehe hore na tlas'a mojaro o matla kapa maemo a tsitsitseng, e na le matla a phahameng a ho monya matla ho feta austenitic stainless steel, e nang le melemo e totobetseng bakeng sa likarolo tsa mohaho ho sebetsana ka katleho le likotsi tsa tšohanyetso tse kang ho thulana, ho phatloha, joalo-joalo, 'me e na le boleng bo sebetsang ba kopo.

S32205 Material Application Areas

Lijana tsa khatello, litanka tse bolokang khatello e phahameng, liphaephe tse nang le khatello e phahameng, li-exchange exchanger (indasteri ea ho sebetsana le lik'hemik'hale).

1.Liphaephe tsa oli le khase, lisebelisoa tsa mocheso oa mocheso.

2.Sistimi ea ho hloekisa likhoerekhoere.

3. Li-classifiers tsa indasteri ea pampiri le pampiri, limela tsa bleaching, polokelo le mekhoa ea phekolo.

4.Li-rotary shafts, li-roll rolls, li-blades, li-impellers, joalo-joalo libakeng tse matla haholo le tse thibelang ho bola.

5.Mabokose a Cargo bakeng sa likepe kapa literaka

6.Lisebelisoa tsa ho lokisa lijo