Moetsi oa Setsebi sa Alloy e hanyetsanang le Corrosion 926/ Inkoloy926/ UNSN08926/ 1.4529

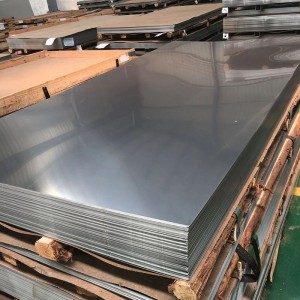

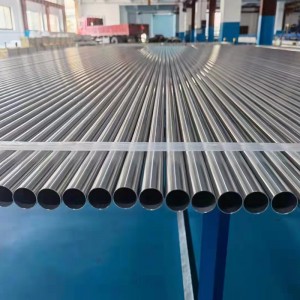

Lihlahisoa tse fumanehang

Tube e se nang seam, Plate, Ropa, Forgings, Fasteners, Pipe Fittings

Maemo a Tlhahiso

| Sehlahisoa | ASTM |

| Bar, Molamu le Mohala | B 649 |

| Letlapa, Leqephe le Lekhapetla | A 240, A 480, B 625, B 906 |

| Liphaephe le Liphaephe tse se nang Metsi | B 677, B 829 |

| Peipi e cheselitsoeng | B 673, B 775 |

| Weld tube | B 674, B 751 |

| Lisebelisoa tsa lipeipi tse cheselitsoeng | B366 |

| Li-billet le li-billet bakeng sa ho qhekella | B 472 |

Sebopeho sa Lik'hemik'hale

| % | Fe | Ni | Cr | Mo | C | Mn | Si | P | S | Cu | N |

| Min | tekatekano | 24.0 | 19.0 | 6.0 |

|

|

|

|

| 0.5 | 0.15 |

| Max | 26.0 | 21.0 | 7.0 | 0.020 | 2.0 | 0.50 | 0.030 | 0.010 | 1.5 | 0.25 |

Lintho Tsa 'Mele

| Botenya | 8.1g/cm3 |

| Ho qhibiliha | 1320-1390 ℃ |

Inkoloy 926 / 1.4529 Thepa ea Lintho

Inkoloy926 / 1.4529 e na le khanyetso e phahameng haholo ea likoti le li-crevice corrosion mecheng ea litaba ea halide le tikoloho ea acidic e nang le sebabole le hydrogen, e khona ho hanela chloride ion stress corrosion, hape e na le khanyetso e ntle ea kutu ho oxidizing le ho fokotsa mecha ea litaba.botsitso le botsitso.E ntle, thepa ea mochini e betere ho feta 904L, e ka sebelisoang ho etsa likepe tsa khatello ea -196 ~ 400 ℃.

INCOLOY Alloy 926 (UNS N08926 / W. Nr. 1.4529 / INCOLOY Alloy 25-6MO) ke tšepe e sa hloekang ea austenitic e nang le 6% molybdenum mme e matlafalitsoe ke ho eketsoa ha naetrojene.Boleng ba nickel le chromium tsa alloy ena li etsa hore e khone ho mamella mefuta e fapaneng ea tikoloho e senyang.Alloy e hanyetsana haholo le li-non-oxidizing acid tse kang sulfuric le phosphoric acid.Dikahare tse phahameng tsa molybdenum le naetrojene di fana ka kganetso kgahlanong le sekoti le maphahlo, ha koporo e eketsa kgahlano le esiti ya sulfuric.

INCOLOY 926 alloy ke 6% molybdenum e tletseng austenitic alloy e nang le khanyetso e ntle ea kutu libakeng tse fapaneng tse senyang, tse nang le metsi.E nkela sebaka sa litšepe tse tloaelehileng tsa austenitic (AISI 316 le 317), moo bokhoni ba bona bo fihletseng meeli ea ts'ebetso ea bona.Ka hona, motsoako ona ke oa sehlopha sa "Super Austenitic Stainless Steels".E ka boela ea emela mefuta e meng e theko e tlaase ho feta li-alloys tse phahameng tsa nickel libakeng tse itseng tsa leoatle le tsa lik'hemik'hale.

E 'ngoe ea thepa e ikhethang ea INCOLOY 926 alloy ke ho hanyetsa libaka tse nang le chloride kapa halide tse ling.Alloy ena e loketse ka ho khetheha bakeng sa ho sebetsana le maemo a phahameng a chloride joalo ka metsi a brackish, metsi a leoatle, caustic chloride le sistimi ea bleaching ea pulp mill.Likōpo li kenyeletsa ho lokisa lik'hemik'hale le lijo, limela tsa ho soeufatsa letlalo le pampiri, lisebelisoa tsa sethala sa leoatleng le lebōpong la leoatle, li-evaporator tsa letsoai, mekhoa ea ho laola tšilafalo ea moea, liphaephe tsa condensate, lipeipi tsa phepelo ea metsi le licheso tsa metsi a fepelang indastering ea motlakase.

Inkoloy 926 / 1.4529 Material Application Areas

1. E na le khanyetso e phahameng ea pitting le crevice corrosion mecheng ea acidic e nang le halides le hydrogen sulfide.

2. Lits'ebetsong tse sebetsang, e sebetsa hantle khahlanong le chloride stress corrosion cracking.

3. E na le khanyetso e ntle ea kutu ho mefuta e fapaneng ea kutu maemong a tloaelehileng a redox.

4. Lisebelisoa tse ntlafetseng tsa mechine ho feta Cronifer 1925 LC-Alloy 904 L.

5. Alloy e ntlafalitse botsitso ba metallurgical ha e bapisoa le li-alloys sebakeng sa 18% sa nickel.

Li-unit tsa flue gas desulfurization bakeng sa tlhahiso ea asiti ea phosphoric, li-evaporator, li-exchangers tsa mocheso, li-filters le li-mixer, lisebelisoa tse tsamaisang sulfuric acid, li-condensers, litsamaiso tse thibelang mollo, mekhoa ea ho hloekisa metsi a leoatle, li-hydraulic le lisebelisoa tsa liphaephe indastering ea offshore, lisebelisoa tsa pulp, condenser ea letsoai evaporative, mochini oa motlakase o silafalitsoeng ke lipeipi tsa metsi a pholileng, sesebelisoa sa ho tlosa letsoai la metsi a leoatle ka morao osmosis, tanka ea polokelo ea lipalangoang tsa lik'hemik'hale tse senyang, lisebelisoa tsa tlhahiso ea lintho tse phelang tsa halogen acid, joalo-joalo.