Alloy800HT/ UNS N08811/ Inkoloy800HT Tube, Plate, Rod

Lihlahisoa tse fumanehang

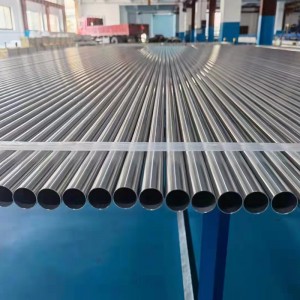

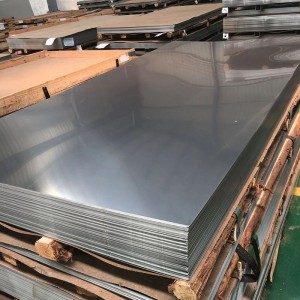

Tube e se nang seam, Plate, Ropa, Forgings, Fasteners, Pipe Fittings

Maemo a Tlhahiso

| Sehlahisoa | ASTM |

| Sebaka | B 408 |

| Letlapa, Leqephe le Lekhapetla | A 240, A 480, B 409, B 906 |

| Liphaephe le li-fittings tse se nang moeli | B 407, B 829 |

| Peipi e cheselitsoeng | B 514, B 775 |

| Lisebelisoa tse cheselitsoeng | B 515, B 751 |

| Khokahano ea solder | B366 |

| Ho qapa | B 564 |

Sebopeho sa Lik'hemik'hale

| % | Fe | Ni | Cr | C | Mn | Si | S | Cu | Al | Ti | P | Al+Ti |

| Min | 39.5 | 30.0 | 19.0 | 0.06 |

|

|

|

| 0.15 | 0.15 |

| 0.85 |

| Max |

| 35.0 | 23.0 | 0.10 | 1.50 | 1.00 | 0.015 | 0.75 | 0.60 | 0.60 | 0.045 | 1.20 |

Lintho Tsa 'Mele

| Botenya | 7.94 g/cm3 |

| Ho qhibiliha | 1357-1385 ℃ |

Bonyane Mechanical Properties Of Inkoloy 800H Alloy Ka Mocheso oa Kamore

| Alloy | Rm N/mm2 | RP0.2N/mm2 | A5 % |

| 800 | 500 | 210 | 35 |

| 800H | 450 | 180 | 35 |

Corrosion Resistance Of Inoloy 800H

Incloy 800H e hanana le mecha e mengata e senyang.Likahare tsa eona tse phahameng tsa nickel li etsa hore e se ke ea hanela khatello ea maikutlo ho senyeha ha maemo a metsi a kutu.Likahare tse phahameng tsa chromium li fana ka khanyetso e betere ea pitting le mapetsong a mafome.Alloy e na le khanyetso e ntle ea kutu ho nitric acid le organic acid, empa ho hanyetsa kutu ho lekanyelitsoeng ho sulfuric acid le hydrochloric acid.Ho hanyetsa kutu ho hotle ka matsoai a oxidizing le a se nang oxidizing, ntle le monyetla oa ho kenya kutu ka har'a halides.E boetse e na le khanyetso e ntle ea ho bola metsing, mouoane le metsoako ea mouoane, moea le carbon dioxide.

Inkoloy 800H e na le Thepa e Latelang

1. Ho hanyetsa kutu e ntle haholo mochesong o phahameng haholo oa metsi a nang le metsi ho fihlela ho 500°C

2. Ho hanyetsa hantle khatello ea maikutlo

3. Ho sebetsa hantle

Inkoloy 800H Libaka tsa Kopo

1. Nitric acid condenser - e hanyetsanang le kutu ea nitric acid

2. Mouoane o futhumatsang tube - thepa e ntle ea mechine

3. Heating element tube - thepa e ntle ea mechine

Bakeng sa lisebelisoa ho fihlela ho 500 ° C, alloy e fanoa ka boemo ba annealed.

LBH

Litheko tsa rona li ka fetoha ho latela phepelo le lintlha tse ling tsa 'maraka.Re tla u romella lenane le ntlafalitsoeng la litheko kamora hore k'hamphani ea hau e iteanye le rona bakeng sa tlhaiso-leseling e batsi.

Ee, re hloka hore liodara tsohle tsa machabeng li be le palo e tsoelang pele ea odara.Haeba u batla ho rekisa hape empa ka bongata bo fokolang haholo, re khothaletsa hore u hlahlobe sebaka sa rona sa Marang-rang

E, re ka fana ka ho fetisisa ditokomane ho akarelletsa le Disetifikeiti tsa Analysis / Conformance;Inshorense;Tšimoloho, le litokomane tse ling tsa thomello moo ho hlokahalang.

Bakeng sa lisampole, nako ea ho etella pele ke matsatsi a ka bang 7.Bakeng sa tlhahiso ea bongata, nako ea ho etella pele ke matsatsi a 20-30 ka mor'a ho fumana tefo ea depositi.Linako tse etellang pele li sebetsa hantle ha (1) re amohetse depositi ea hau, 'me (2) re na le tumello ea ho qetela bakeng sa lihlahisoa tsa hau.Haeba linako tsa rona tsa ho etella pele li sa sebetse le nako ea hau ea ho qetela, ka kopo sheba litlhoko tsa hau ka thekiso ea hau.Maemong 'ohle re tla leka ho fana ka litlhoko tsa hau.Maemong a mangata re khona ho etsa joalo.